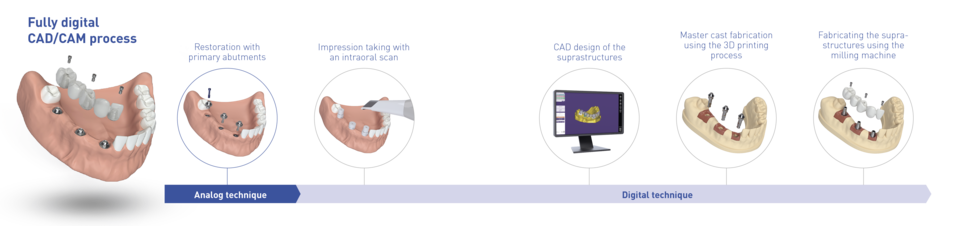

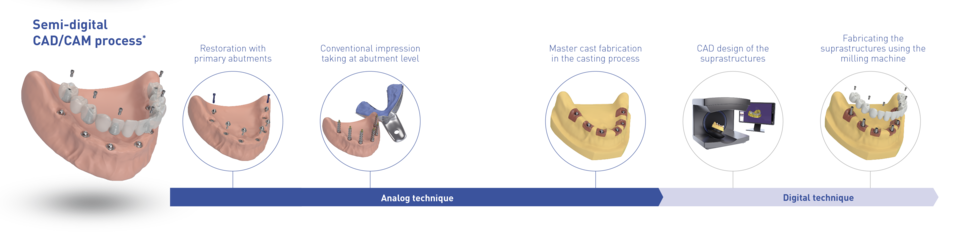

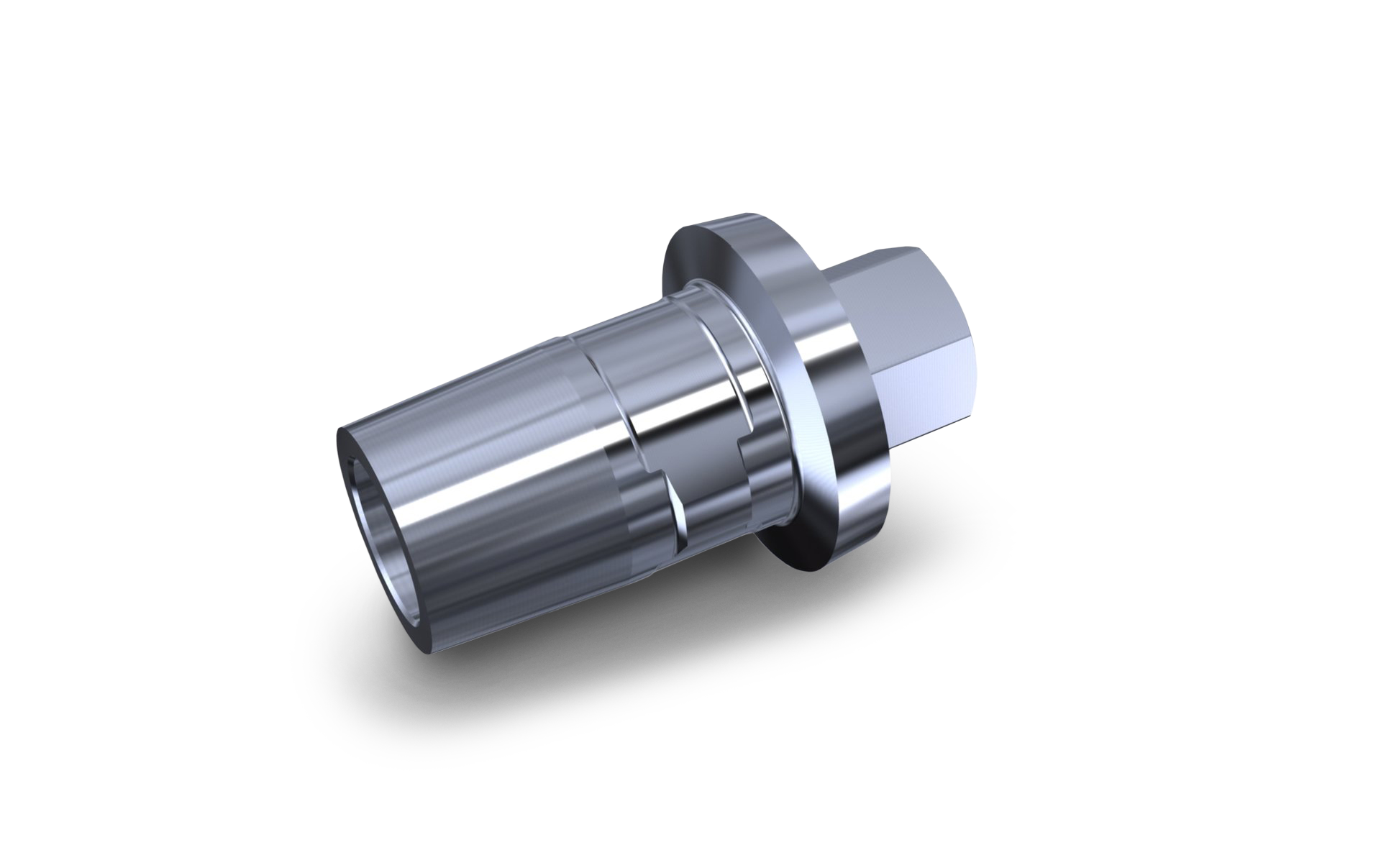

VARIOmulti titanium base for CAD/CAM

• Flexible - you can shorten the height of the titanium base (shortenable) to fit the suprastructure and the materials used

• Ideal for multi-unit bridges with large divergences of the implant axes – the conical geometry ensures a stress-free, precise insertion of the prothesis

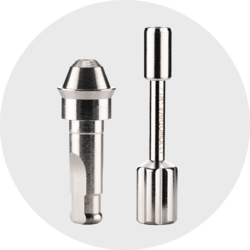

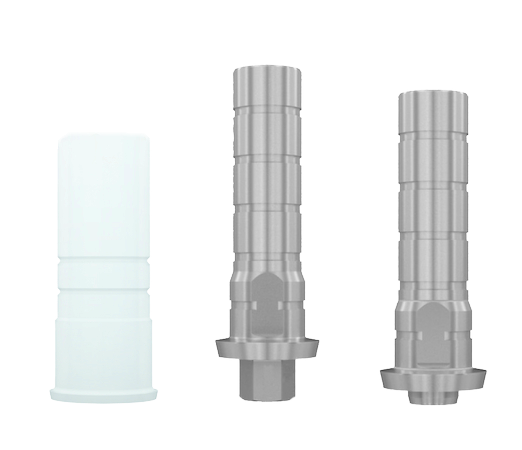

VARIOmulti analog for CAD/CAM and its insertion aid

• Secure and reliable positioning – particularly suitable for 3D-printed master casts and plaster casts, thanks to an ingenious design and high-precision manufacturing

• Easy and efficient insertion – with the aid of the sophisticated holding system and well-designed insertion aid

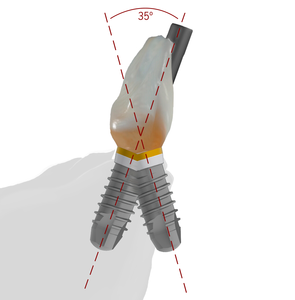

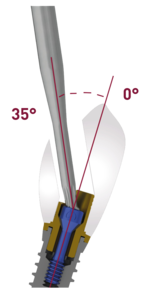

Dynamic Tibase®

Flexible and independent in the choice of attachment.

Do not let the implant axis determine the fixation option, but decide for yourself. The Dynamic Tibase® is ideally suited for esthetically demanding screw-retained restorations. With the Dynamic Tibase® it is possible to design the screw channel up to 35° deviating from the implant axis. This allows you to use screw-retained restorations even in situations that could previously only be restored with a cemented solution.

Benefits at a Glance

- Part of digital workflow.

- Angle deviations of up to 35°.

- The adjustable height cylinder ensures optimal support of the superstructure.

- Two different abutments types: standard and with adjustable height.

VARIOflex

The VARIOflex abutment meets a variety of clinical requirements and stands for flexibility in the selection and design of prosthetic restorations.

The VARIOflex abutment can be used for both screw-retained and cemented restorations. Thanks to its slim and solid design, this abutment is suitable for both the posterior and the esthetically demanding anterior region.

The CAD/CAM-compatible abutments can be adapted to the clinical situation and material-specific requirements. The CAD/CAM library offers the selection of different cylinder heights with only one abutment during the manufacturing process. The abutments have been specially developed for restorations with plastic, pressable ceramics and zirconium oxide and offer the best possible support - both for long or high superstructures and for deeper-set implants.

CAD/CAM libraries are available for the VARIOflex abutment. For detailed information, please refer to the corresponding instructions for use.

Electronic instructions for use – VARIOflex - THM611119

Benefits at a Glance

- Digitally applicable.

- Flexible material selection: Plastic, press ceramic, metal and zirconium oxide.

- Prosthetic variety with one design.

- Enables high superstructure.

Titanium Base for CAD/CAM

CAD/CAM Libraries

Instructions for use - Titanium Base for CAD/CAM - THM61123

Benefits at a Glance

- Efficient digital manufacturing.

- Individual emergence profiles.

- Cemented or screw-retained crown and bridge restorations possible.

Milling Abutment for CAD/CAM type II

The Milling Abutment for CAD/CAM type II makes it possible to create individually manufactured abutments.

The milled abutment for CAD/CAM type II is machined in the Original Medentika® PreFace Abutment Holder in a suitable milling system. PreFace Abutment Holders can be ordered directly from the milling machine manufacturer. You can also obtain information on the use of the Medentika® PreFace Abutment Holder from your milling machine manufacturer.

Instructions for Use - Milling Abutment for CAD/CAM type I & II - THM61137

Benefits at a Glance

- In-house production - the added value remains with you

- Individual abutments with original Thommen Medical implant connection.

- Efficient production - serial processing of six blanks without reclamping.

Benefits at a Glance

- Simple: Insertion within seconds with a clearly perceptible click.

- Ergonomic handling thanks to the insertion aid for implant analogs.

- The well thought-out design of the outer geometry and the clever layout of the analog seat create the conditions for a precise fit in the model.